Moog Leverages SOLIDWORKS Cloud PDM

Speeding the Design Process Through Revision Control

Headquartered in Asheville, NC, employee-owned Moog Music is known in the industry as the leading manufacturer of theremins and analog synthesizers. Founded as R. A. Moog Co. in 1953 by 19-year-old Robert Moog and his father, the company has continuously produced groundbreaking electronic musical instruments that have profoundly influenced modern music since the mid-sixties.

In the past, the mechanical design team at Moog Music relied on a local server to maintain files and run its SOLIDWORKS 3D CAD software. They needed a new system to improve file management, keep pace with SOLIDWORKS upgrades, and reduce security vulnerabilities associated with an out-of-date operating system.

The team speculated that a cloud-based solution might better meet its PDM requirements, at the same time improving security and avoiding the cost of replacing the server. Lack of a modern PDM system was slowing the product development process, making it difficult to keep CAD files up-to-date, recalls Engineering Manager and Mechanical Design Lead Steven Hobbs. Comments Hobbs, “Our biggest concern was revision control. It was a little like the Wild Wild West.”

Smooth and Easy Implementation

According to Hobbs, the company’s IT department didn’t even need to get involved. The implementation took place remotely with minimal guidance. “The smoothness and ease of the cloud implementation by Converge stand as a testament to the company’s expertise and technology. The process was seamless and the support has been great. We couldn’t be happier.”

Adds Engineering Support Technician Homer Jenkins, “It happened really quick. Installation and set-up were so straightforward that we just had to exchange a few emails.”

Working Remotely, Increasing Productivity

The old server for the mechanical design department at Moog Music didn’t allow VPN, making it hard to access files while traveling or working from home, a necessity during the pandemic of course. With the cloud server, designers can now access software and files more securely. Explains Ragsdale, “Timing was important. We started in January 2020 and by March the design team was ready to rock-and-roll from home. It was a seamless transition for everyone.”

Hobbs estimates that he has reduced his own work time from 5 to 15% with SOLIDWORKS PDM Standard because he no longer needs to spend hours determining which CAD files are the latest and then distribute them.

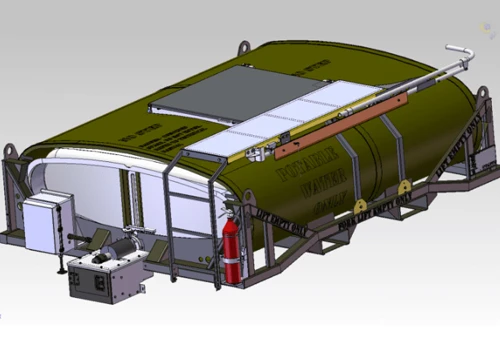

Saving Additional Time With Flatter Files

Along with PDM in the cloud, Moog Music’s product development process has made life a lot easier for the design team by means of a cloud-based third-party product known as Flatter Files, which ties into the PDM Vault so that design files stay up-to-date. This solution allows anyone in the organization to download 3D design data in a 2D pdf format for manufacturing purposes from any phone, tablet, or PC. Flatter Files also allows the creation of STEP files, which contain 3D data in a format recognized by multiple CAD programs, ideal for certain CNC processes.

Realizing that in most cases SOLIDWORKS users were the only individuals who actually needed access to the SOLIDWORKS 3D files, Flatter Files has proven a valuable investment. It has eliminated conflicts with non-SOLIDWORKS files and the hassle of manual file conversion, as well as distribution. What’s more, the team plans to eventually roll out Flatter Files to its suppliers.

Plans for the Future

In addition, the growing design team at Moog Music is keenly interested in providing connection and cross-communication with the company’s ERP system, which is used to facilitate better supply chain management.

ECN control is a hot button for the design team too, supplying a means of authorizing and recording design changes. Within the next two years the team anticipates adding ERP and ECN connectivity by upgrading from SOLIDWORKS PDM Standard to the professional version of the software.

Concludes Hobbs: “The main advantage of working with Converge is that the staff offers a unique combination of both cloud and SOLIDWORKS software expertise. Converge's know-how is helping us produce better products and maintain leadership in our industry.”

Fossil

Learn how Converge and EpiGrid provided Fossil with an infrastructure that immediately solved their collaboration issues with their globally distributed design team.

Choctaw Defense

Learn how Converge helped implement a cloud-hosted PDM vault that met all DOD compliance standards for data management.